- 中文

- English

Date:2020.03.31 Number of readers:118

The customer used a 12000rpm spindle to run on the machining. After the speed has been reached 10,000 rpm, the spindle was often overheated (Both front and rear side’s temperature rises has been exceed 18 ° C).Having this situation so could not be longer continued running.

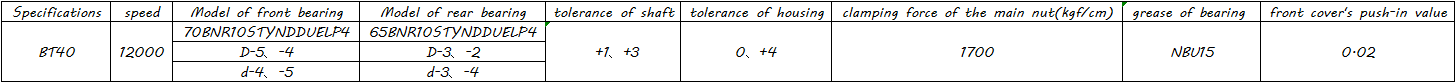

< Figure1> Related values of the original spindle

This spindle was used Japanese brand of 7014 series bearings with small steel ball (The limit speed only could be reached 10000rpm, so exceeding this speed could be easily caused the problem of overheat.)

Reason:

Due to the special design of the spindle structure, the front-end bearings were need to carefully select (including the groove curvature of bearing raceway, material of cage, parameters of bearing application, etc.)

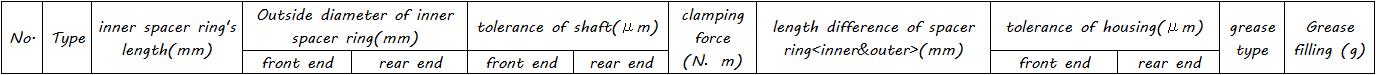

The front end’s spindle bearings were replaced by TIMG’s 12000rpm bearings with small ceramic balls (ball diameter : φ7.938mm, 29 rolling elements).Accurately calculate values of reasonable assembly and provide the proposal for one-time installation.< Figure 2 >

< Figure2> With the above information provided by the customer, TIMG can effectively calculate the proposal for one-time installation.

Solution:

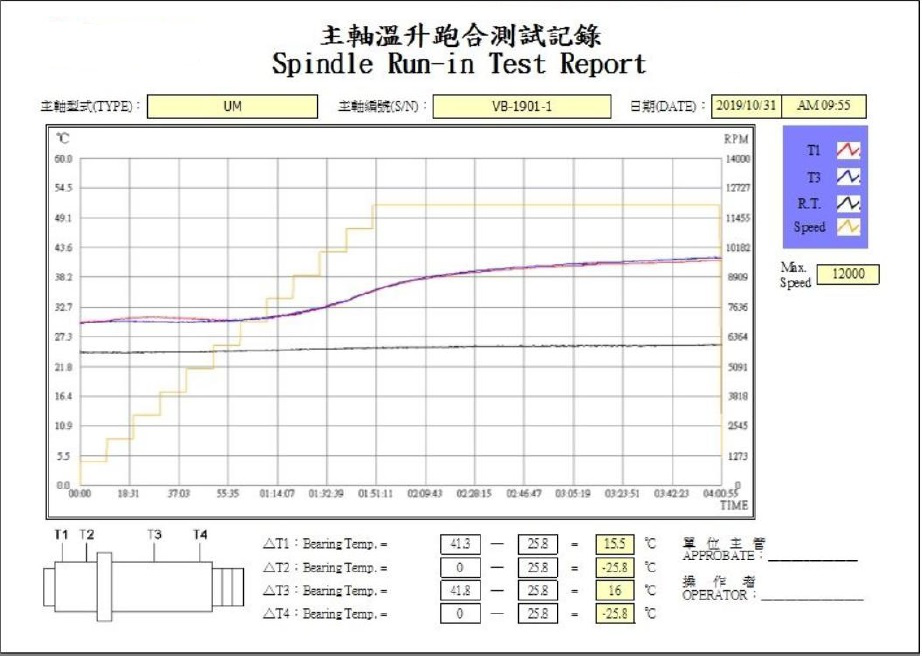

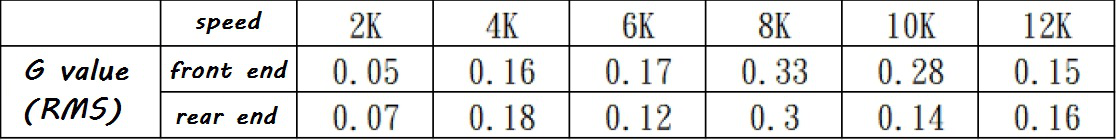

By the replacement of bearings and strict control of the assembly value for spindle assembly, also precise running process, not only allow the spindle can be reached to the limit speed till 12000rpm for days, but also temperature rise at the front end’s bearing is about 15 ° C<Figure 3>,and the G value is also within 0.35RMS <Figure 4>, which are all normal standard values.

By the replacement of bearings and strict control of the assembly value for spindle assembly, also precise running process, not only allow the spindle can be reached to the limit speed till 12000rpm for days, but also temperature rise at the front end’s bearing is about 15 ° C<Figure 3>,and the G value is also within 0.35RMS <Figure 4>, which are all normal standard values.

< Figure3> When the speed reaches the limit, the temperature rise is stable. <Figure4>G value is within 0.33RMS, which is a normal standard value.